FLOX®: Fire without flame - efficient, clean and stable

FLOX® stands for » FLameless OXidation « und describes the combustion technology which was discovered by Dr.-Ing. Joachim A.Wünning in the early 90's. Since this time it was continuously improved and is today the basis of all our burners.

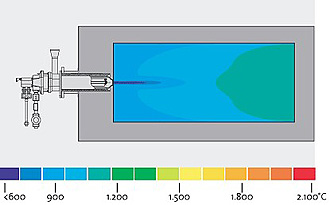

The following figure shows the temperature distribution in a furnace operated in FLOX® mode.

Fuel and combustion air react in a homogeneous reaction volume downstream of the burner nozzles, whereas in traditional flame combustion the reaction takes place in a highly intensive reaction zone attached to the burner nozzles. The ignition is induced by the recirculation of hot combustion gases.

This results in lowest NOx emissions, even when high air preheating is applied. Furthermore, it allows to burn low calorific value gases without any problems on flame stability. Due to this

homogeneous distributed reaction the temperature stress caused by peak temperatures is low and average temperatures can be increased significantly without changing the materials of the boiler.