Gas treatment plants

Combustion of residual gases from biogas processing

Using biogas sensibly – protecting the climate effectively

Biogas from agricultural plants or landfills is a valuable, renewable energy source. By separating CO₂ and nitrogen, it can be purified to such an extent that the remaining methane can be fed directly into the natural gas grid or used as liquid methane as a climate-friendly fuel. This replaces fossil natural gas and significantly reduces CO₂ emissions.

However, residual methane remains in the separated gas stream. And it is precisely this gas that has a particularly strong greenhouse effect. In order not to burden the climate balance, it must be oxidised safely. This is where e-flox comes in: we have developed highly efficient low-pressure gas combustion plants that are specially optimised for PSA and membrane gas treatment.

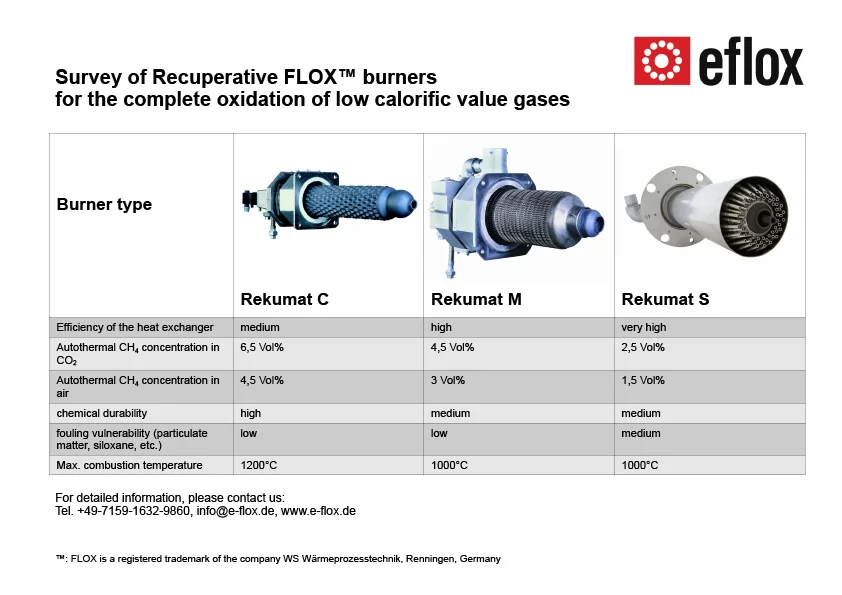

Our technology makes intelligent use of the exhaust heat: combustion air and residual gas are preheated before entering the combustion chamber, allowing different autothermal operating points to be achieved depending on the preheater. This means that methane is burned reliably and without additional fuel – even with varying residual gas compositions or possible contaminants such as H₂S or siloxanes.

After combustion, the exhaust gas has a temperature of between 250 and 800 °C, which is ideal for generating heat. This enables our plants to achieve residual heat utilisation with an efficiency of up to 85%.

Although we offer proven standards, we develop each solution individually – precisely tailored to your plant, your residual gas quality and your requirements.