The principle

The FLOX® Technology

FLOX® – Efficient and low-emission combustion technology

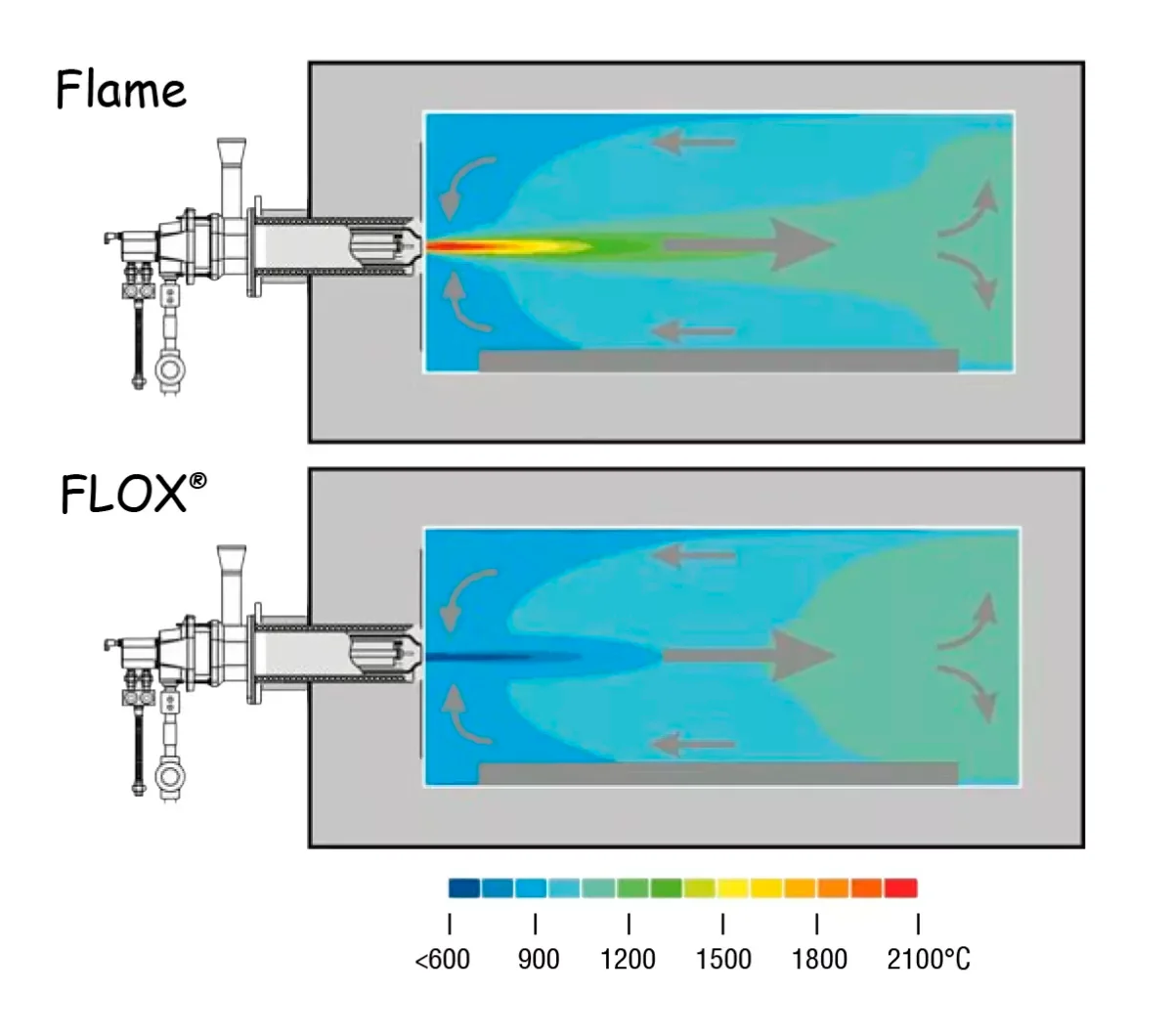

The enormous potential of FLOX® became apparent immediately upon discovery of the effect: the disappearance of the visible flame and its characteristic noise, as well as a drastic reduction in NOx emissions with complete combustion.

Fire without flame – an apparent contradiction that has proven to be a groundbreaking innovation. This combustion principle opens up a wide range of applications in many different variants, particularly in the steel industry and in burners for heat treatment, and offers decisive advantages. Unlike conventional burners, the intelligent mixing of fuel gas, combustion air and recirculated exhaust gas in FLOX® burner operation prevents extreme temperature peaks during combustion. This allows the efficiency gains achieved through high air preheating rates to be exploited without increasing NOx emissions. In addition, the even temperature distribution in the furnace ensures both high-quality products and a significant reduction in burner wear – decisive factors for environmentally conscious operation, economic efficiency and consistently high product quality.

However, the potential of FLOX® technology is far from being exhausted. Numerous national and international projects – some of which are supported by subsidies – are focusing on future fields of application in thermal process and energy technology. For years, particular attention has been paid to adapting our burners to the special requirements of climate-friendly fuels such as hydrogen, ammonia and methanol. Wasserstoff, Ammoniak oder Methanol.